AUTONOMOUS WATER SUPPLY COMPLEXES FOR HOTELS AND HIGH-RISE RESIDENTIAL HOUSES.

Nowadays, challenging issue of water supply for high-rise hotels and residential houses is urgent enough. Quality of water and water supply provided by the municipal services is far from ideal. Pressure drops, up to complete lack of water, low quality of supplied water (bed organoleptic parameters anddisturbing in its tendency bacteriology) get the residents down, despite of usually available technical and financial possibility to resolve this problem.

Main objects of the system:

- increasing efficiency of water supply facility;

- creating emergency water reserve;

- increasing quality of water supply (ensuring lack of pressure jumps and consequently resulted fluctuations in temperature of cold and hot water mixture);

- increasing quality of water;

- reducing costs (minimizing expenses for service life of the proposed equipment).

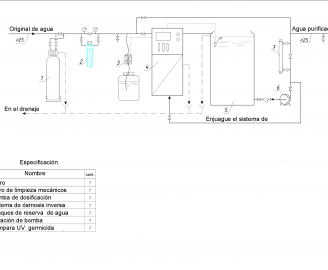

- Description of process diagram.

Optimum layout for water supply facility is the layout containing group of water reserve tanks and pump station aimed to ensure uninterrupted water supply even, when there is lack of water at the entry point. As a weak point for this variant we consider a risk of bacterial contamination of water in the reserve tanks.

To decrease risk of bacterial contamination of water we offer installing the water treatment unit. The offered water treatment unit is capable not only to eliminate contamination of water stored in the reserve water tanks, but as well to improve organoleptic and bacteriological parameters of the supplied water.

The process diagram, provided in fig.1 includes the following main elements:

- Water treatment unit.

- Pump station.

- Group of hydraulic accumulators.

2.1. Water treatment unit.

We offer for water supplied from a metering station to a house to be directed to the water treatment unit, which includes the following elements:

a. Air discharge facility

To prevent air in water supply system in the moment, when water supply restarts, we offer installing air discharge facility.

b. Mechanicalcleaningfilter.

Mechanical cleaning filter is a QSF filter (fr. 0,4 – 0,8 mm), which is intended to remove mechanical impurities and suspended substances (sludge, rust particles, soils, etc.) from water. Average estimated purification rate 10-15 mcm. Estimated effect of muddiness decrease ≈ 25-30%.

In proportion to accumulation of the contaminations (once per three days at 2 a.m.) the filter is automatically delivered for washing with rising water flow and discharges the accumulated contaminations to drain. Filter is washed with pure water supplied from the reserve tanks and containing ions of dissolved silver (see below), that improves washing effect, ensures disinfection of QSF, reduce amount of rinsing water and prevents filter washing under low input pressure.

c. Sorption purification filter.

Sorption purification filter is a pressure filter with complex catalytic filtration media (manganese zeolite BIRM and copper & ceramic granules KDF). This filter is designed to remove from water dissolved and colloidal impurities, organic substances and active chlorine.

Use of this filter for water purification allows removing bad taste and odor, contributing to color fading (contributes to water clarification). Estimated effect of color fading ≈ 20-25%.

Estimated effect of decrease of permanganate value ≈ 15-20%.

Amount of rinsing water for two filters per month – 5,25 m3 ,

What is 1,9 % of monthly water consumption.

d. Apparatus for water conservation with dissolved silver ions (silver ionizer) is designed for water conservation with dissolved silver ions; it increases water resistance to bacterial contamination. It prevents blooming of water stored in the reserve tanks, occurring stale odor and taste, forming slime (biofilm) on the internal surfaces of the reserve tanks, pipes and plumbing systems. Silver ionizer switches on and switches off automatically depending on water passage.

Ten-year practice of using silver ionizers proves reliability and efficiency of this apparatus.

Capacity – 2,0-2,5m3/h;

Power consumption – 10 W;

Voltage – 24V;

Silver dose – 0,01-0,02 mg/l;

Service life of the silver electrodes – 6 years;

3. Pump station.

Water is supplied from the reserve tanks to the consumers due to pumping station. Detailed description of the equipment and operation of the pumping station is given below.

Based on hydraulic calculations, the best configuration of the pumping station includes double stage pumping station containing two pumps with different capacities (1 stage pump and 2 stage pump) and two hydraulic accumulators with capacity 100 liters each, installed on upper technical stage.

Installation of hydraulic accumulators on upper technical stage is needed primarily because within the period of maximum water draw-off, water from the hydraulic accumulators, located at upper stage, will be discharged to the water supply system from up to down (towards to the main flow) and will be supplied to upper stages, therewith reducing rising height and hydraulic losses, while supplying residual consumption.

Herein it should be noticed that the cold water risers shall be connected to each other as along the bottom and on the top (looped). Alsoitcontributestoreliability, comfortandefficiency. So, in case of non-uniform water draw-off to the risers, water will run to the draw-off points of the overloaded riser along two directions: from down – from the pumps, and from up – from near located risers and hydraulic accumulators resulting uniform distribution of pressure along the whole system and eliminating pressure differentials in some separate point

2.3 UV antibacterial facility.

We recommend to install two UV antibacterial facilities with capacity 5m3 each to the pressure pipeline following the pumping station; UV antibacterial facilities will become the last antibacterial barrier on the way to the customers. After installation of UV antibacterial facilities, we offer tying in a circulation pipeline, equipped with electromagnetic valve, controlled with a time-delay relay. Therefore, once per a day at 4 am the electromagnetic valve opens for 15-minute period and water begins circulating through the loop “reserve tank – pumping station – reserve tank”. 15-minute period is enough sufficient to give the water stored in the reserve tanks run through UV antibacterial facilities.

Power consumed by 2 facilities – 2 х 110 = 220W;

Service life of UV lamps – 1 year.

High level of reliability, lack of reagents (pelleted, etc.), replacement cartridges as well as low power consumption (maximum 30W/h) form significant advantage for the offered purification unit. Annual maintenance is necessary and sufficient for the whole system maintenance interval.

Pellentesque adipiscing leo condimentum enim ullamcorper pretium. Aenean gravida, libero nec convallis ornare, massa odio.

Pellentesque adipiscing leo condimentum enim ullamcorper pretium. Aenean gravida, libero nec convallis ornare, massa odio.