Sub Categories

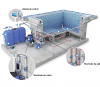

TRATAMIENTO DE 3 ETAPAS EFICIENTE Y EFECTIVO

1. COMPARTIMENTO DE PRE-TRATAMIENTO: Una planta comercial de Jet para el tratamiento de aguas residuales utiliza componentes como filtros de rejilla, trituradores de basura y trampas para capturar objetos grandes y desintegrar todo lo que no pueda ser tratado, tal como plástico o metal, para que no puedan entrar en el proceso de tratamiento. Estas aguas residuales pre-tratadas son enviadas al Tanque de Aireación.

2. TANQUE DE AIREACIÓN: Los difusores de aire de Jet colocados al fondo de la Cámara de Aireación introducen grandes cantidades de aire y lo mezclan rigurosamente, llenando la demanda de oxígeno que necesita el proceso de digestión aeróbica. Este proceso asegura el tratamiento adecuado de las aguas residuales pre-tratadas durante las 24 horas que permanecen las mismas dentro del tanque. El resultado es un líquido incoloro e inodoro completamente tratado, que está listo para pasar al Tanque de Sedimentación/Clarificación.

3.TANQUE DE SEDIMENTACIÓN/CLARIFICACIÓN: En este tanque, las aguas residuales ya tratadas se mantienen en total reposo para que las pequeñas partículas restantes viajen al fondo del tanque y regresen nuevamente al tanque de Aireación para tratamiento adicional. Solamente un efluente claro y altamente tratado puede salir de la planta de Jet y ser descargado al medio ambiente en forma segura.further treatment.

EN EL NÚCLEO DE NUESTRO SISTEMA:

EN EL NÚCLEO DE NUESTRO SISTEMA:

EL EXCLUSIVO DIFUSOR DE AIRE DE JET

A medida que el aire es bombeado hacia la cámara da aireación, en el ciclo de “encendido”, los bordes de nuestros difusores de aire sellado rompen el flujo de aire en pequeñas burbujas resultando en una óptima transferencia de oxígeno. Los difusores también hacen la vez de válvulas de retención impidiendo que las aguas residuales y el lodo activado se regresen y obstruyan las líneas de aire cuando la planta se encuentra en el ciclo de “apagado”. Una bolsa de aire queda atrapada bajo cada difusor, por encima de la línea de agua, para proteger el sistema de aire de JET. La realidad es que nuestro sistema es el único en el mercado verdaderamente libre de obstrucciones.

RENDIMIENTO SUPERIOR, LA MÁS LARGA VIDA ÚTIL POSIBLE, MANTENIMIENTO MÍNIMO, PROTECCIÓN Y SEGURIDAD COMPLETA … GARANTIZADA

Las plantas comerciales de Jet cumplen y exceden los estándares aceptados y han sido aprobados por diversos departamentos de salud local, estatal y de distritos.

• Los tanques libres de corrosión son construidos con concreto (hormigón) reforzado permanente. No hay necesidad de preocuparse por unidades de ánodos.

• Tenemos tanques de la medida correcta y con la capacidad de aire correcta para tratar desde 1,500 a 100,000 galones de aguas residuales por día para cualquier instalación en cualquier lugar.

• Componentes mecánicos y eléctricos en los tamaños adecuados y previamente ajustados.

• Todos los equipos mecánicos son fabricados de acuerdo a requerimientos específicos y operan a una velocidad segura.

• Si necesita aumentar la capacidad de su planta, tenemos módulos de tanques disponibles para una fácil expansión.

• Garantía limitada anual y de una sola fuente a partir de la fecha de envío.

• La más rápida entrega e instalación en la industria.

• Distribuidores profesionales y locales capacitados por Jet instalan, prueban, ponen en marcha, y procuran el mantenimiento de, cada planta y componente que fabricamos.

• Los tanques de concreto son fabricados en su localidad, eliminando altos costos de transportación y envío.

• Vertedero de efluente fácil de ajustar que le ahorra costos de mano de obra, y que son accesibles por la parte de arriba de la planta para una fácil nivelación.

• Rejillas de alta resistencia con barras de acero galvanizado, que se pueden cerrar con llave, protegen la operación de la planta permitiendo que se pueda caminar sin peligro durante las inspecciones, lo que provee una alta protección y seguridad.

• Las boquillas de control para rociar espuma de Jet reducen considerablemente cualquier riesgo de obstrucción mientras se rocía en un patrón exacto, sobre la superficie del Tanque de Aeración.

• Una amplia gama de tamaños de plantas para ajustarse a cualquier requerimiento de instalaciones.

• Su distribuidor de Jet capacita a sus empleados en cuanto a la operación y mantenimiento de la planta, y periódicamente la inspecciona durante el primer año sin costo adicional para usted.

• Luego del primer año de funcionamiento de su planta, usted puede hacer arreglos con su distribuidor de Jet para obtener servicio continuo.

• Incluimos instrucciones claras, precisas, y fáciles de seguir dentro de su manual de operaciones, junto con diagramas de cableado y procedimientos de servicio para todos los componentes.

• Si usted necesita ayuda en cualquier momento, el nombre y la información para contactar a su distribuidor local de Jet se encuentra impresa en una placa permanentemente adherida a su nueva planta.

Tenemos disponibles cada opción que usted pueda necesitar, incluyendo sistemas de desinfección con cloro JET-CHLOR para desinfectar cualquier fluido que su planta tenga que tratar, tabletas Accu-Tab, sistemas CLHOR-AWAY para reducir el contenido de cloro, estaciones de bombeo, equipo alternativo de respaldo, Sistemas de Control para Rociar Espuma de Jet con salida de agua de lavado, equipo de regulación de flujo, filtros de rejillas con barras fijas, canastas de rejillas con barras removibles, relojes con programación para 7 días, tomacorrientes de 115 voltios, su elección en cuanto a voltaje y fases, silenciadores de entrada, vertederos con medidor de flujo, equipo de retención y aireación adicional de lodos, registro de medidas de flujo, amoladores/trituradores, alarmas de nivel de líquidos… lo que sea que usted necesite para un mayor rendimiento de su nueva planta de Jet, lo tiene dispo-nible su distribuidor local de Jet.

FTL introduces for Spain market the solution of American company “Jet” designed to treat waste waters of the residential premises.

Waste waters are treated with biological purification method without using chemicals and with use of proper natural resources; due to this method waste water, within 24 hours, turns to transparent liquid without odor. This method uses patented bioreactor, where oxygenated microorganisms attaches to submerged JET’s BAT media, forming biomass, which is ready to purify waste waters quickly and efficiently. Due to lack of mechanical filters, which need maintenance, biological treatment plant JET1500 BATMEDIAPLANT can operate up to 5 times longer than a septic tank.

The plant JETBAT intended to treat waste waters for the residential premises, decomposes wastes by running them through three-compartment tank. The first compartment is intended for the preliminary treatment; it receives influent and here heavy solids settle and form sludge at the bottom of the tank. The second compartment is intended for water treatment. Here wastewater or grey water is thoroughly mixed with oxygen via 700++ aerator and passed over the living microorganisms located on Jet’s BAT.This is an exclusive process designed and developed by Jet Inc. and is more efficient than purification with chemical agents; this method was developed and was being practically used within more then 5 years. Treated wastewater or grey water then flows to the settling compartment. A clear liquid, devoid of color and odor, is supplied to a customer via special dust.

A Jet home wastewater treatment plant is capable of treating 500 to 1,500 gallons of wastewater each and every day. No loading of water supply lines, no season can effect the performance of a Jet home wastewater treatment plant.

Quality of waste water treatment using Jet treatment plants allow using purified waste water for subsoil irrigation or for irrigation of the industrial crops. As well, purified waste water can be discharged to a water basin for public and household needs (not for fishery). Advanced treatment unit or bio plateau (a ground with gravel bottom layer, planted with bulrush) ensure purification level sufficient to allow discharging water to fishery basins.

In order to use purified waste water for pool, you need to apply the ultrafiltration (UF) system for wastewater treatment.

Such systems are called MBR-reactors (membrane-type biological reactors), which cost more expensive then waste water treatment plants, as well as their maintenance, but anyway, in Spain, any investment to water treatment results significant saving of cash, sufficient profit in future and safety to nature.

Specifications of the systems for biological wastewater treatmentJET1500 BATMEDIAPLANT

| No. | Type | Number of residents, persons | Capability, m3/day | Dimensions, HxLxB, m | Power consumption, W |

| 1 | J-500 | 10 | 1,8 | 1,7x3,1x1,5 | 250 |

| 2 | J-750 | 15 | 2,7 | 1,7x3,1x1,5 | 250 |

| 3 | J-1000 | 20 | 3,6 | 1,7x3,1x1,5 | 500 |

| 4 | J-1250 | 25 | 4,5 | 1,7x3,1x1,5 | 500 |

| 5 | J-1500 | 30 | 5,4 | 1,7x3,1x1,5 | 500 |

Amount of purified waste water corresponds to the current requirements for water discharge to a water basin for public and household needs:

- BOD5 – max 15 mgО2/l (BOD – biochemical oxygen demand)

- Suspended matters – max. 15 mg/l

Advantages of the systems for biological treatment JET1500 BATMEDIAPLANT

- Ideal for small houses and cottages

- Substitutes outdated septic tanks avoiding all corresponding problems: odor and sludge

- Easily transported and mounted

- Unit for Jet’s BAT media provides up to 80 m2 of surface area for useful microorganisms, which form biomass necessary for biological treatment

- Due to aerator applied for this system, no other manufacturer in the industry matches our quality, reliability or the overall long-life.

- No other manufacturer matches Jet’s warranty service repair policy.

- 5-years warranty is provided for Jet aerator.

Technology to prepare water for the pools is designed by FTL in cooperation with Jetincotrpс aimed to improve comfort level and operation parameters of the pools to maximum. First of all, the designed solutions are intended to leave behind usually used chlorine-containing agents and, at the same time, to improve bacteriological safety. However, in respect to the current pools, previously used water preparation equipment shall not be demounted, but updated by additional installation of new unit.

1. The main problems, occurring in a period of use of pools, which are subjects for standard water preparation technologies.

Standard technology for preparation water for the pools includes the following scheme for water treatment:

1. рН – correction;

2. Water treatment with chlorine containing agent (routine, periodic and etc.);

3. Filtration of water on a filtering unit with and without use of flocculants.

For long-term use of pools, which are subjects for above mentioned water treatment procedure application, the following procedures shall be applied:

1. Increase of salt content in water, which relate to constant evaporation of containing fresh water. In addition, while the filtering unit operates correctly, loss of water, which discharges, when filters are rinsed and further adding water to the pool can compensate increased salt content only partially. Once a year or even more frequently, half amount of water or even complete amount of water in the pool shall be replaced, but this procedure is expensive enough.

2. Increase of salt content and concentration of organic substances in water of pools results increased hardness, alkalinity and chlorine absorptivity of water. This fact results need to increase doses of рН-correcting substances and chlorine containing reagents as well it results formation on the walls of the pool of a hard-to-remove limy stripe on “water-air” boundary.

3. Use of chlorine-containing agents and related formation of volatile chloroorganic compounds hardly look perfect in the context of view of up-to-date vision.

2. Short description of the offered technology.

This purification technology for water used for the pools, while preserving the filtering unit, provides the following stages:

- installing reverse osmosis system and Silver Ionizer to the line for adding water;

- installing ozone treatment system and UV antibacterial facility on the circulation line (after filtering unit).

Process chart for water preparation is given on fig. 1.

To prepare the best technical and commercial proposal concerning the system for water preparation and purification to use it for any pool in Spain, we need to know the following information:

- cubature of a pool, m3

- location of a pool ( inside or outside)

- maximum number of swimmers , man/day

- dimensions (plan) of currently used or planned premise to install the equipment

- currently used equipment intended to supply (pumps) and purify (capacity is m3/h) water

AUTONOMOUS WATER SUPPLY COMPLEXES FOR HOTELS AND HIGH-RISE RESIDENTIAL HOUSES.

Nowadays, challenging issue of water supply for high-rise hotels and residential houses is urgent enough. Quality of water and water supply provided by the municipal services is far from ideal. Pressure drops, up to complete lack of water, low quality of supplied water (bed organoleptic parameters anddisturbing in its tendency bacteriology) get the residents down, despite of usually available technical and financial possibility to resolve this problem.

Main objects of the system:

- increasing efficiency of water supply facility;

- creating emergency water reserve;

- increasing quality of water supply (ensuring lack of pressure jumps and consequently resulted fluctuations in temperature of cold and hot water mixture);

- increasing quality of water;

- reducing costs (minimizing expenses for service life of the proposed equipment).

- Description of process diagram.

Optimum layout for water supply facility is the layout containing group of water reserve tanks and pump station aimed to ensure uninterrupted water supply even, when there is lack of water at the entry point. As a weak point for this variant we consider a risk of bacterial contamination of water in the reserve tanks.

To decrease risk of bacterial contamination of water we offer installing the water treatment unit. The offered water treatment unit is capable not only to eliminate contamination of water stored in the reserve water tanks, but as well to improve organoleptic and bacteriological parameters of the supplied water.

The process diagram, provided in fig.1 includes the following main elements:

- Water treatment unit.

- Pump station.

- Group of hydraulic accumulators.

2.1. Water treatment unit.

We offer for water supplied from a metering station to a house to be directed to the water treatment unit, which includes the following elements:

a. Air discharge facility

To prevent air in water supply system in the moment, when water supply restarts, we offer installing air discharge facility.

b. Mechanicalcleaningfilter.

Mechanical cleaning filter is a QSF filter (fr. 0,4 – 0,8 mm), which is intended to remove mechanical impurities and suspended substances (sludge, rust particles, soils, etc.) from water. Average estimated purification rate 10-15 mcm. Estimated effect of muddiness decrease ≈ 25-30%.

In proportion to accumulation of the contaminations (once per three days at 2 a.m.) the filter is automatically delivered for washing with rising water flow and discharges the accumulated contaminations to drain. Filter is washed with pure water supplied from the reserve tanks and containing ions of dissolved silver (see below), that improves washing effect, ensures disinfection of QSF, reduce amount of rinsing water and prevents filter washing under low input pressure.

c. Sorption purification filter.

Sorption purification filter is a pressure filter with complex catalytic filtration media (manganese zeolite BIRM and copper & ceramic granules KDF). This filter is designed to remove from water dissolved and colloidal impurities, organic substances and active chlorine.

Use of this filter for water purification allows removing bad taste and odor, contributing to color fading (contributes to water clarification). Estimated effect of color fading ≈ 20-25%.

Estimated effect of decrease of permanganate value ≈ 15-20%.

Amount of rinsing water for two filters per month – 5,25 m3 ,

What is 1,9 % of monthly water consumption.

d. Apparatus for water conservation with dissolved silver ions (silver ionizer) is designed for water conservation with dissolved silver ions; it increases water resistance to bacterial contamination. It prevents blooming of water stored in the reserve tanks, occurring stale odor and taste, forming slime (biofilm) on the internal surfaces of the reserve tanks, pipes and plumbing systems. Silver ionizer switches on and switches off automatically depending on water passage.

Ten-year practice of using silver ionizers proves reliability and efficiency of this apparatus.

Capacity – 2,0-2,5m3/h;

Power consumption – 10 W;

Voltage – 24V;

Silver dose – 0,01-0,02 mg/l;

Service life of the silver electrodes – 6 years;

3. Pump station.

Water is supplied from the reserve tanks to the consumers due to pumping station. Detailed description of the equipment and operation of the pumping station is given below.

Based on hydraulic calculations, the best configuration of the pumping station includes double stage pumping station containing two pumps with different capacities (1 stage pump and 2 stage pump) and two hydraulic accumulators with capacity 100 liters each, installed on upper technical stage.

Installation of hydraulic accumulators on upper technical stage is needed primarily because within the period of maximum water draw-off, water from the hydraulic accumulators, located at upper stage, will be discharged to the water supply system from up to down (towards to the main flow) and will be supplied to upper stages, therewith reducing rising height and hydraulic losses, while supplying residual consumption.

Herein it should be noticed that the cold water risers shall be connected to each other as along the bottom and on the top (looped). Alsoitcontributestoreliability, comfortandefficiency. So, in case of non-uniform water draw-off to the risers, water will run to the draw-off points of the overloaded riser along two directions: from down – from the pumps, and from up – from near located risers and hydraulic accumulators resulting uniform distribution of pressure along the whole system and eliminating pressure differentials in some separate point

2.3 UV antibacterial facility.

We recommend to install two UV antibacterial facilities with capacity 5m3 each to the pressure pipeline following the pumping station; UV antibacterial facilities will become the last antibacterial barrier on the way to the customers. After installation of UV antibacterial facilities, we offer tying in a circulation pipeline, equipped with electromagnetic valve, controlled with a time-delay relay. Therefore, once per a day at 4 am the electromagnetic valve opens for 15-minute period and water begins circulating through the loop “reserve tank – pumping station – reserve tank”. 15-minute period is enough sufficient to give the water stored in the reserve tanks run through UV antibacterial facilities.

Power consumed by 2 facilities – 2 х 110 = 220W;

Service life of UV lamps – 1 year.

High level of reliability, lack of reagents (pelleted, etc.), replacement cartridges as well as low power consumption (maximum 30W/h) form significant advantage for the offered purification unit. Annual maintenance is necessary and sufficient for the whole system maintenance interval.

| Name | SKU | Description | Category | Producer | ||

|---|---|---|---|---|---|---|

Reverse osmosis system

|

Reverse osmosis system, to be installed in the feeding line, is designed for desalination of water entering into the swimming pool. |

Water for pools |

|

|||

| Ozone water treatment system |

Ozone water treatment leads to splitting of a large range of organic substances entering into the swimming pool |

Water for pools |

|

|||

| Bomba centrífuga DWO | Centrifugal pumps |

|

||||

| Bomba centrífuga GCS | Centrifugal pumps |

|

Pellentesque adipiscing leo condimentum enim ullamcorper pretium. Aenean gravida, libero nec convallis ornare, massa odio.

Pellentesque adipiscing leo condimentum enim ullamcorper pretium. Aenean gravida, libero nec convallis ornare, massa odio.